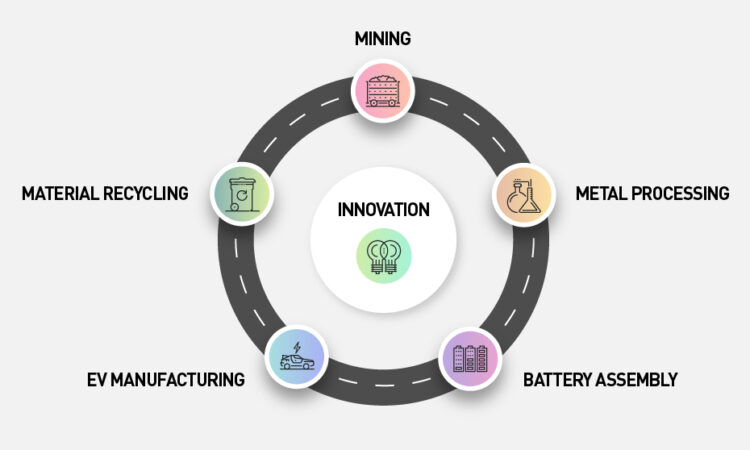

The battery value chain for automotive and transportation captures the step-by-step process to produce batteries that are needed in the industrial transformation and the electrification of the automotive and transportation sectors. It guides a “mines to mobility” approach to developing a sustainable Canadian battery ecosystem for transport and electric vehicles

Mineral exploration and mining

Raw materials are extracted to create lithium-ion batteries, which are used in EVs. The minerals needed are:

- lithium

- cobalt

- nickel

- graphite

- manganese

Metal processing and precursors

The raw materials are transformed into battery-grade mineral concentrates or intermediate products, known as precursors. Precursors are the key element for the manufacturing of cathodes and anodes, the active materials essential to the production of battery cells used in EVs and transportation.

Battery components, cells and pack manufacturing

The cathodes and anodes, as well as other components like electrolytes, copper foil and separators, are moulded to form individual cells. These cells are then packed into modules to construct a lithium-ion battery.

Manufacturing of EVs and parts supply

Modules and parts are sent to suppliers and manufacturers to create lithium-ion batteries and to assemble EVs.

Material recycling and circular economy

At the end of life for lithium-ion batteries, the materials and metals are recovered and reprocessed for recycling and reutilization purposes in order to ensure a sustainable and green value chain.

Brummionline